When I got back on the LP, it was a lot of head scratching and layout. I first dug the fuselage out of the corner of my hangar. I was curious how straight it was. When I got it leveled longitudinally and laterally in front and checked it at the tail, it was mostly level or no more than .1 degree off. The wing mounts were also level. This was all very encouraging!

|

| Fuselage leveled and checked for straightness |

It was then time to start thinking about cabane struts. I have no struts, only OX-5 Swallow drawings from which the LP is a close copy.

When Victor Roos left Swallow to go to Lincoln-Page, he took with him the OX-5 Swallow design. That is why the airplanes resemble each other. However, the airplanes are different in many areas. Unfortunately, all the LP drawings were apparently destroyed in a flood. A very interesting letter I have in my collection is from Victor Roos's wife. When Andy bought the airplane from Chuck Balling (the original owner) in 1966, he tried to acquire information and wrote to Mrs. Roos. I find the letter very funny as she has "neither time or inclination to look over files of old documents..."! By the way, the letter is addressed to Ken Ward. Ken was a neighbor of Andy's who helped research things with the airplane as Andy was busy with his career at United Airlines.

|

| Letter from Hazle Roos - Victor Roos's wife |

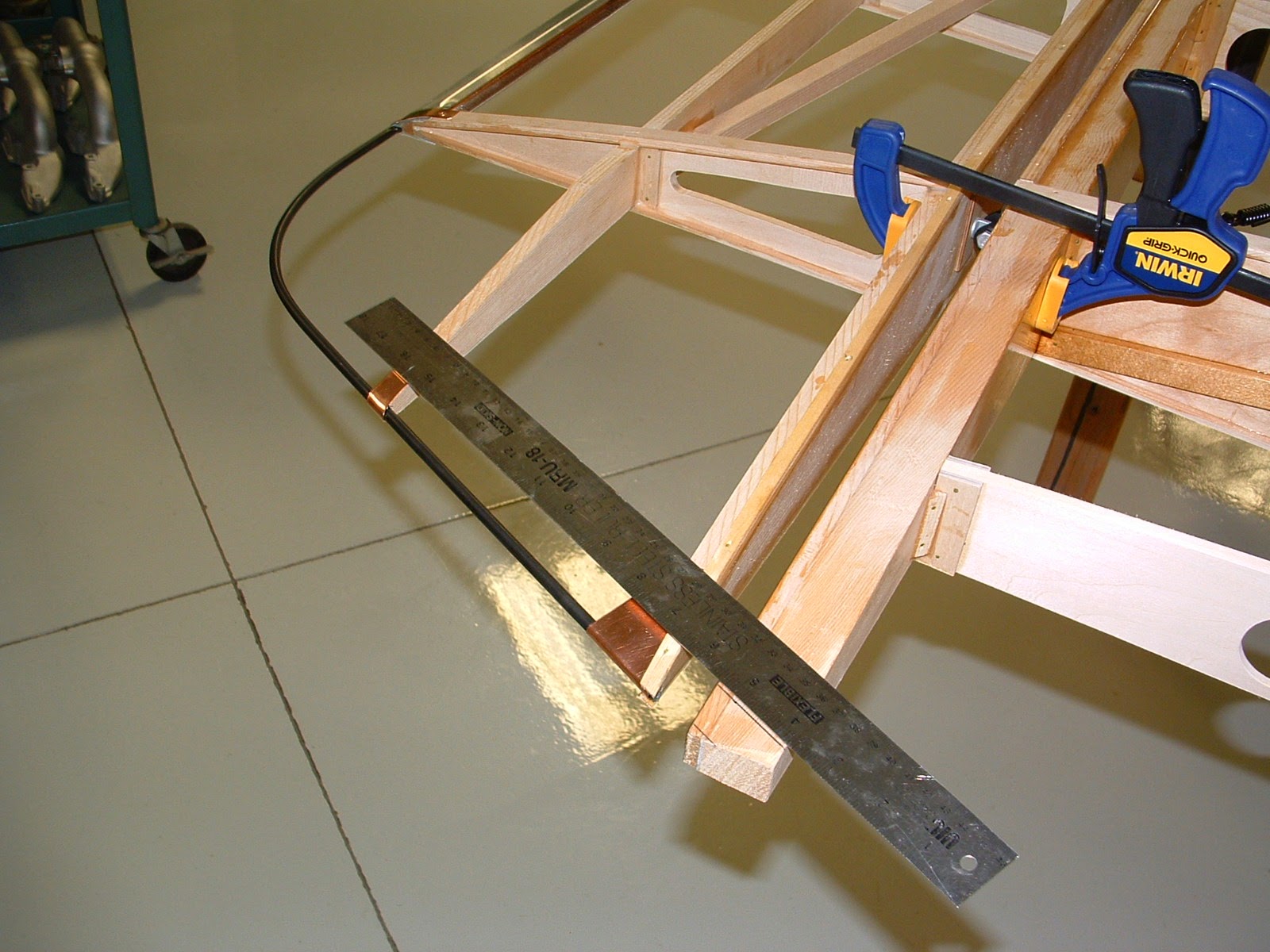

Back to the cabanes...I tried to do all the layout by using trig functions, but wasn't getting a good feeling that things were working out OK. I decided to make wood cabane mock-ups so I could take hard dimensions off the airplane. A much better approach! I started with the Swallow dimensions and in the end, those numbers came out very close - even with the angle of incidence of the 2 airplanes being different.

|

| Mock-up of cabane struts |

There are only 3 variable that can be controlled/adjusted with the cabane struts: stagger, gap, and angle of incidence. For the LP, these specs are:

- Stagger - 29% positive or 16 degrees

- Gap - 60 inches

- Angle of incidence - 1 degree upper wing, 1.5 degrees lower wing (not adjustable)

My friend Mark came over to help, and with levels, plumb bobs, etc., we got it worked out. So I now have all the strut lengths for the cabanes. Streamline strut material is on order, and will be made once that material arrives.

In the meantime, I'm going over the fuselage with a fine-tooth comb. Adjusting and correcting all attach points, tubing, etc that is bent or tweaked. In addition, I'm adding more stand-offs on the tubular metal stringers to keep them from bowing in as the fabric covering is shrunk.

It will probably be a couple more weeks until the next update - there is just a lot more thinking and less doing going on right now!