I've been trying to add new posts to this blog once a week, but really didn't accomplish much last week to make it worthwhile. This first wing is taking extra long since I have to figure out everything as I go. Sometimes it's one step forward, two steps back! As an example, the fittings I made sometime back that attach to the drag/anti-drag wires had to be modified. The fittings were made from .100" 4130, the correct thickness for the original fork on the turnbuckle end. New, modern turnbuckle forks have a larger opening, so I had to weld a .050" shim to these fittings.

|

Original fork on left, new on right with shim

added to fitting. |

Besides that little setback, I got 2 coats of traditional spar varnish on the spars and main ribs - will do the nose ribs and trailing edge ribs after they are installed. I wanted the interior part varnished first before the brace wires and fittings were installed. The N-strut fittings were also completed.

|

| Varnished wing panel with fittings installed |

|

| N-strut (interplane) fittings |

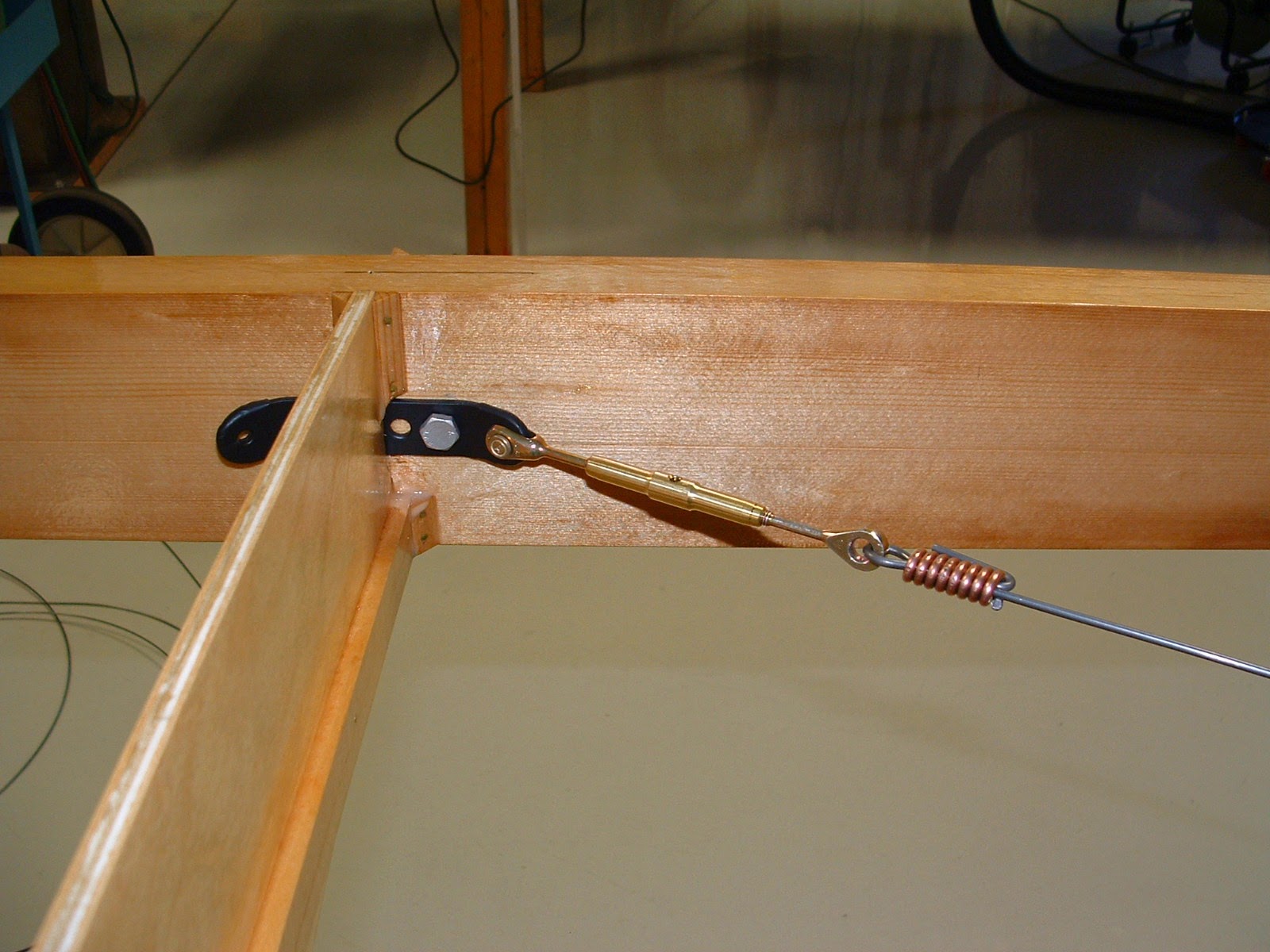

I completed the structure for the wing walk area as well with exception of the plywood sheeting on top. I'll attach it after the nose and trailing edge ribs are installed and the wing in trammed. Fittings were painted and attached, and I was finally able to fit, make and install the drag/anti-drag wires.

|

| Wing walk structure and brace wires |

What's next? I removed all the brace wires for paint. Will reinstall them and start adding nose and trailing edge ribs.

I like the P-47 in your hangar apartment.Is it for sale?

ReplyDelete